All of us at SEAMAX CANADA want to thank you for choosing a Seamax Inflatable boat. Seamax Inflatable boats are designed like larger boats with excellence in mind. We have carefully thought out every detail from the overall boat design to the smallest component application.

We also thank you for reading this instruction manual. This manual has 2 main sections. The boat section of this manual contains all the safety and operating information, boats’ spec and features, how to assemble the boat and how to give maintenance to the product. The accessories section of this manual contains many great Seamax made boat accessories information, some of the products could be the best friend of your inflatable boat so you can’t miss them. So please read this manual and store it in a safe place for future reference. And you can download this manual from our website if you want to check anything new.

The operator, passengers and water craft are governed by local, state, provincial, national, and when applicable, international rules and regulations of the waterways. If you are not familiar with these rules and regulations, your local Department of Natural Resources or boating course can assist you. Safety courses are available from national and local organizations and are highly recommended for anyone who is not familiar with the rules and regulations of safe operation of water vessels.

Seamax Inflatable Boat comes with a limited 5 years warranty from SEAMAX CANADA or local Seamax boat dealers. The detail warranty terms and conditions are in the Warranty Section of this manual. Keep this booklet and your sales slip together for future reference. You may be asked to provide proof of purchase for in-warranty service. For any questions or concerns about our products or service, you can email us and we will respond as quickly as possible.

When inflating the boat, Seamax DO NOT recommend customer to use the regular air compressor. Inflatable boats are not designed to be inflated with high pressure air compressors. This may cause the seams to rupture or the air valves to malfunction. This in turn could create a dangerous situation and personal injury could occur if a seam was to rupture. This type of inflation will void your warranty. If you are looking for a portable electric air pump for this boat, you can purchase Seamax 12V Boat Electric Air Pump that built in the pressure monitoring and auto stop features.

To record the boat Hull Identification Number (HIN) and engine series number is very important. The HIN is located on the hull plates on the transom. The engine model and serial number are located on the swivel bracket. You will need all those information to obtain parts, warranty service or provide information to your local law enforcement agency if your boat is lost or stolen. You can record those information right now including - Owner Name & Contact Information; Boat Model & Series Number; Engine Model & Series Number and Proof of Purchase.

SEAMAX Inflatable Boats are warranted to be free of defects in material and workmanship during the following prescribed warranty period. All warranty claims are handled in USA or Canada by Seamax or local Seamax dealers.

The boat’ hull, floor, all hull attachments and accessories, but not limited to, such as floorboards, D-rings, oar lock holders, safe rope, lifting handles, air valves, seat receiver, bench seat, carrying bags, foot pump, oars, drain valve and transom integrity are covered by this Limited Warranty for one (1) year from the date the product first sold or delivery. All the air holding fabrics and transom seam structure are warranted against defects in material or workmanship that cause blistering and delaminating for three (3) years, and five (5) years for (PVC) fabrics. The repair, replacement of parts, or the performance of service under this warranty does not extend the life of this warranty beyond its original expiration date. Unexpired warranty coverage can be transferred to a subsequent purchaser upon proper registration of the product.

This Warranty applies only to defects in material and workmanship; it does not apply to normal wear and tear, or to damage caused by below reasons: (1). Neglect, lack of maintenance, accident, commercial, abnormal or improper use or bad assembly; (2). Use of an accessory or part neither manufactured nor sold by us; (3). Participating in or preparing for races or other competitive activity; (4). Alteration or removal of parts; (5). Improper Protection against UV-light, high temperature and heat sources; (6). Has been repaired, modified or tampered with by someone other than manufacturer without approval; (7). Damage or deterioration of the fabric due to exposure to fuel, harsh solvents or any other chemicals; (8). Seam separation due to heat exposure; (9). Has not been assembled, used, and maintained in accordance with the instructions or owner's manual accompanying the product; (10). Boat has been damaged as a result of shipping, warehousing or storage.

SEAMAX limited warranty does not cover incidental or consequential costs and expenses such as haul-out, launching, towing transport and storage charge, telephone or rental charges of any type, inconvenience, waste of time or income losses, or other consequential damages.

The consumer must provide COMPLETED access to the product for warranty service by delivering the product for inspection to SEAMAX or a dealer authorized to service the product. If the warranty claim can be without sending the product back, Seamax may require photos and detail description in email. Our obligation under this warranty shall be limited to repairing a defective part, or at our discretion, refunding the purchase price or replacing such part or parts as shall be necessary to remedy ANY defect in material or workmanship as covered by this warranty.

To be eligible for warranty coverage, the product (Seamax inflatable boat) must be registered with SEAMAX within 30 days from purchase except the purchase is from Seamax Directly or Seamax Online.

SEAMAX limited warranty is transferable to a subsequent purchaser for the remainder of the unused portion of the warranty. This will not apply to products used for commercial applications. To transfer the warranty to the subsequent owner, send us a (a) Copy of the Bill of Sale or (b) Purchase Agreement within 30 days of transfer. Warranty Claims may not be accepted without proper presentation of boat title transfer.

Seamax head office is located in Richmond, BC. Canada. Also, we are the manufacturer of Seamax inflatable boats and accessories. Products are designed in Canada and with our best guarantee.

If you need assistance or service, please first refer to this booklet. Additional help is available by visiting our website, contacting us or visiting any local Seamax dealers. Remember, your satisfaction with your inflatable boat is very important to us.

Seamax Marine (Canada Head Office) 120-11791 Machrina Way, Richmond, BC, Canada V7A 4V3 http://www.seamaxcanada.com http://www.seamaxmarine.com Email: support@seamaxcanada.com sales@ seamaxmarine.com TEL: 1-877-907-7766 1-604-277-7766 Fax: 1-604-277-3360

The operator (driver) is responsible for the correct and safe operation of the boat and safety of its occupants and general public. It is strongly recommended that each operator (driver) read and understand this entire manual before operating the boat. Be sure at least one additional person on board is instructed in the basics of starting and operating the outboard and boat handling in case the driver is unable to operate the boat .Remember in Canada you must have a boating certification license for all motorized watercraft. All local rules and regulations apply to all waterways. If you have any questions or concerns, please feel free to contact with us. Safety and operating information that is practiced, along with using good common sense, can help prevent personal injury and product damage.

Boater’s operation license is required in Canada and USA when use the boat with an outboard engine or electric motor. Your boat may have to be registered with Transport Canada or DMV office (Department of Motor Vehicles) before use. Please make sure you and your boat can meet all the government requirements when you transport the boat on the land or use the boat in the water.

The purpose of a lanyard stop switch is to shut down the engine in an emergency situation when the operator moves from a safe operating distance (as in accidental ejection from the operator's position) to activate the switch. Tiller handle outboards and some remote control units are equipped with a lanyard stop switch. A lanyard stop switch can be installed as an accessory, generally on the dashboard or side adjacent to the operator's position. Should the operator fall out of the boat, the possibility of serious injury or death from being run over by the boat can be greatly reduced by stopping the engine immediately. Always properly connect both ends of the stop switch lanyard to the stop switch and the operator.

The lanyard is coiled to make its at-rest condition as short as possible to minimize the likelihood of lanyard entanglement with nearby objects. Its stretched-out length is made to minimize the likelihood of accidental activation should the operator choose to move around in an area close to the normal operator's position.

It is very difficult for a person standing or floating in the water to take quick action to avoid a boat heading in his or her direction, even at slow speed. Always slow down and exercise extreme caution any time you are boating in an area where there might be people in the water. Whenever a boat is moving (coasting) and the outboard gear shift is in the neutral position, there is sufficient force by the water on the propeller to cause the propeller to rotate. This neutral propeller rotation can cause serious injury. Shift outboard into neutral and shut off the engine before allowing people to swim or be in the water near your boat.

Operating recreational boats over waves and wakes is a natural part of boating. However, when this activity is done with sufficient speed to force the boat hull partially or completely out of the water, certain hazards arise, particularly when the boat re-enters the water.

The primary concern is the boat changing direction while in the midst of the jump. In such a case the landing may cause the boat to veer violently in a new direction. A sharp change in direction can cause occupants to be thrown out of their seats or out of the boat. Use extreme caution when near other boats. There is another hazard from allowing your boat to launch off a wave or wake. If the bow of your boat pitches down far enough while airborne, upon water contact it may penetrate under the water surface and submarine for an instant. This will bring the boat to an instant stop and can send the occupants flying forward. The boat may also steer sharply to one side on impact with the water .please be aware of these wave and wake hazards and use extreme caution.

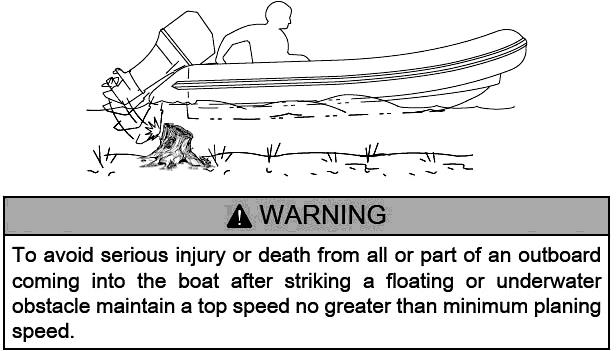

Reduce speed and proceed with caution whenever you drive a boat in shallow water areas, or in areas where you suspect underwater obstacles may exist. These obstacles could be struck by the bottom leg of the outboard or the boat bottom and cause severe damage to the boat and or motor. Travel these areas with extreme caution, to reduce injury or impact damage from striking a floating or submerged object reduce your boat speed.

Boat operators should complete a boating safety course. And the boat operator may need to pass a Pleasure Craft License to operate any motorized craft on the water (mandatory in Canada). In order to safely enjoy the waterways, familiarize yourself with local and other governmental boating regulations and restrictions, and consider the following suggestions:

1) On hand have enough life-Jackets (or personal floatation devices) with you for all your Passengers.

2) Check the pressure and the condition of the boat before you start your trip or sailing.

3) Pay close attention to the updated weather conditions for your safety, and tide table if necessary.

4) Do not forget the important stuffs like oars, safety kit, working flash light, map and boating license.

5) Make sure you take repair kits, first aid kit and a MANUAL air pump with your boat.

6) Make sure you do not exceed the maximum recommended number of persons on the capacity plate

7) Do not exceed the max horsepower rating. We recommend the boat with 50-75% of max HP motor.

8) Make sure enough fuel or battery power for the trip, unusually 30% to go, 30% back and 40% spare.

NOTE: Use of alcohol or drugs is prohibited while operating a water craft. Alcohol or drug use impairs your judgment and greatly reduces your ability to react quickly. This carries the same penalty as driving a car if convicted.

Have an approved personal flotation device of suitable size for each person aboard the vessel (it is the law) and have it readily accessible at any time. Do not overload your boat. Boats are rated and certified for maximum load (weight) capacities (refer to your boat capacity plate). Perform safety checks and required maintenance. Follow a regular schedule and ensure that all repairs are properly made. Know and obey all nautical rules and laws of the waterways.

Prepare other boat operators. Instruct at least one other person on board in the basics of starting and operating the outboard, and boat handling, in case the driver becomes disabled or falls overboard. Stop the engine whenever passengers are boarding, unloading, or are near the back (stern) of the boat. Just shifting the outboard into neutral is not sufficient. The operator of the boat is responsible by law to maintain a proper lookout by sight and sound. The operator must have an unobstructed view particularly to the front. Never operate your boat directly behind a water skier in case the skier loses control and hits the water .Use extreme caution around any swimmer, diver or persons in the water.

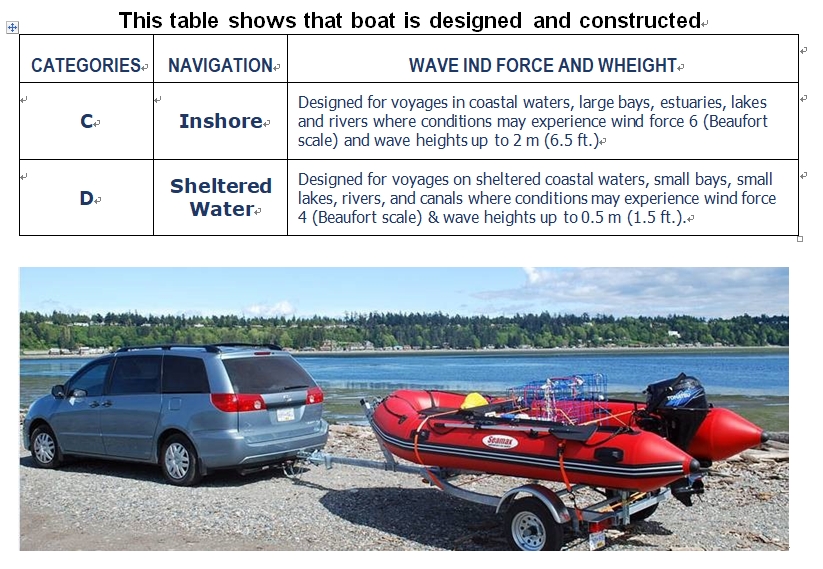

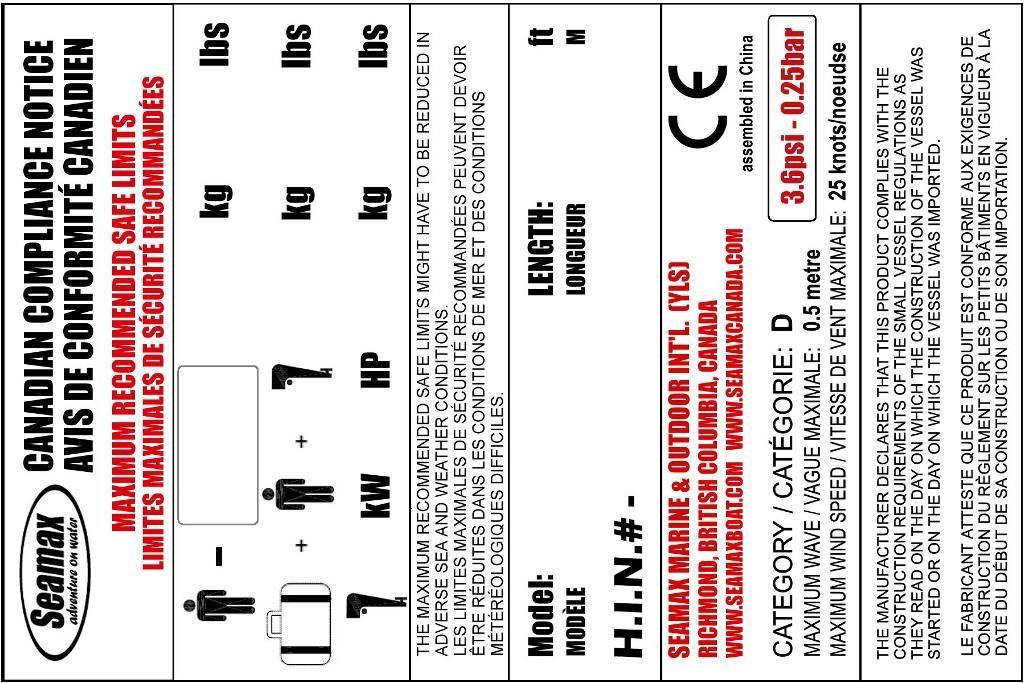

Seamax inflatable boats are registered by transport Canada by following the Small Vessels Manufacture Standard TP1332E and carry our own manufacture's identification code. Each Seamax boat carries a capacity plate along required by Transport Canada .This certification along with the CE certification allows Seamax Boats to be sold worldwide

Seamax is a registered inflatable boat manufacturer with Transport Canada and is treated as a registered boat builder for US Coast Guard. Inflatable boats are probably the most stable boats on the water. They are used for offshore rescue, whitewater rafting and are the boat of choice for most military agencies. Seamax Inflatable boats come in several different sizes and floor combinations. Seamax Marine is the developer and distributor of Seamax inflatable boats and accessories.

The Seamax new features listed below could be base on commercial standard of inflatable boat, upgrade from commercial standard or Seamax self-develop. All those features will let our boat more rigid, more durable comparing with many other boats. And we can guarantee the Seamax boats can with longest life time. Thanks again for choosing Seamax.

Description – FOS

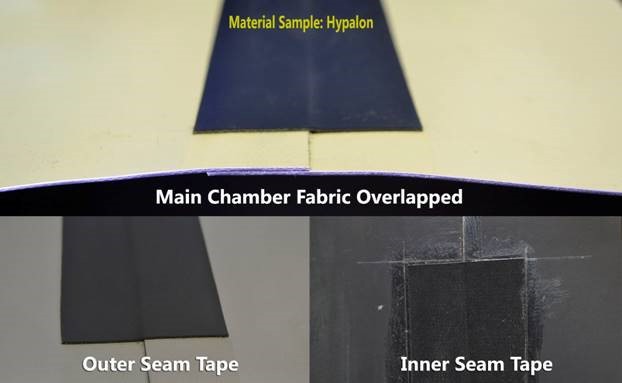

4 layers overlap seam finishing is the strongest seam construction standard in the inflatable boat industry. The 2 main chamber fabrics are bonded together with ½” overlapped. And there are 2 extra 1” pieces of seam tape on both sides to reinforce the main seam. Total thickness of FOS seam is about 4-5mm thick and 2.5” wide. (Applied on most Seamax selection)

Seamax inflatable boats with FOS standard have a strong pontoon chamber which is air tight and will have a longer life expectancy. FOS Seamax chamber seams are better at resisting sun and heat damage over the long term. Demo photos show the FOS seam applied on Hypalon material. Now the FOS standard has been used on all our new boats including PVC & Hypalon.

Double Hot Welded Standard - Seamax do double hot welded seam as the highest industry standard. After the main chamber fabric welded together, we add another sky-blue seam tape welded from chamber inside to reinforced and double the result. We also add a 2nd body color seam tape from outside for the boat a best looking and extra reinforced.

Description – IBR

The Inner Bottom Reinforcement Layer is located on the boat bottom central keel area (inside). It is a simple idea but gives a lot of extra protection for your boat bottom. The IBR coverage is about 3' x 1' for small boats and up to 5' x 2' on larger boats. Seamax has used our IBR standard to build heavy duty boats since 2010. The IBR system is not visible from the outside of the boat and causes no extra water resistance when out on the water. IBR standard has been in effect since 2011 on our selected models.

Benefit – IBR

The IBR system makes the hull more rigid and it's a great feature to have on your boat as it protects your boat when launching the boat from the beach or from a trailer. It also increases hull thickness in the event you hit something that's submerged in the water. Seamax has had zero damage claims since the IBR standard has been in effect. (Applied on most Seamax foldable boat selection)

Description - TSR

Boat transom is glue with pontoon and bottom all together. Sun light, water and temperature can severely damage the transom structure on roll up inflatable boats. Adding extra stability and protection to the transom is very important to build our Seamax boats. Besides using marine grade solid birch plywood to increase the quality, we have developed new manufacturer standards that focus every points of making. We call our standard Transom Stabilizer Reinforcement (TSR). The TSR feature has been used on Seamax commercial grade catalogue.

Benefit - TSR

TSR makes the boat and transom much stronger, the transom adaptors are fully reinforced with 2 additional layers from top and bottom. The fabric coverage of transom is increased and double layer. TSR will help the pontoon disperse the outboard motor vibration and weight. The reinforcement technology will dramatically extend the overall life time of our Seamax inflatable boats.

Description - HSB

The Hull Stabilizer Bar (HSB) was designed by Lawrence (Owner of Seamax) and first applied on our government project. Now Seamax HSB (2nd version) is available on every Seamax Ocean T model boat, or all Seamax boats over 14ft. (Photo of TSR is not showing on our website). The TSR feature has been used on the Seamax Ocean T series only.

Benefit – HSB

Located near the front deep V-Hull, the specially made HSB greatly helps stabilize the boat structure. The tension along the HSB creates an invisible force triangle to stabilize the front Hull and keep the floor in place. Such a triangle inner support for the hull is a great boat feature that no body having. Also, a boat using the HSB feature will have better high speed boating performance, and the reinforced hull structure allows the boat driven safely when chambers in low pressure

Description - AHQC

Seamax has created the Accurate Hull Quality Control (AHQC) as part of our manufacturing standard. This AHQC standard is included. As part of our new standard boat design which includes a new cutting pattern for both the pontoon and boat bottom, a new floorboard standard, new equipment and properly trained staff. Because of all these changes and updates, our inflatable boat can offer a tight and superior finished bottom as compared to other manufacturers.

Benefit - AHQC

The AHQC standard may help increase max boat speed up to 15% and reduce possibility of damage in use. The rollup inflatable boat bottom is very hard to build tight and smooth. Seamax has learned how to properly design a rollup inflatable boat that does NOT have this problem. It costs more time, technique and money to make perfect boats, and that could be why many manufacturers have problems with their boat hulls

* Reflective Tape for Night Navigation

US Coast Guard Approved 3M Reflective Sheeting; Color Code: White USCGFP30 (Sliver). Commercial Grade Reflective Tape Dimensions: 3”x10”, 3”x8”. Applied QTY is based on boat length.

* This feature is optional on selected models.

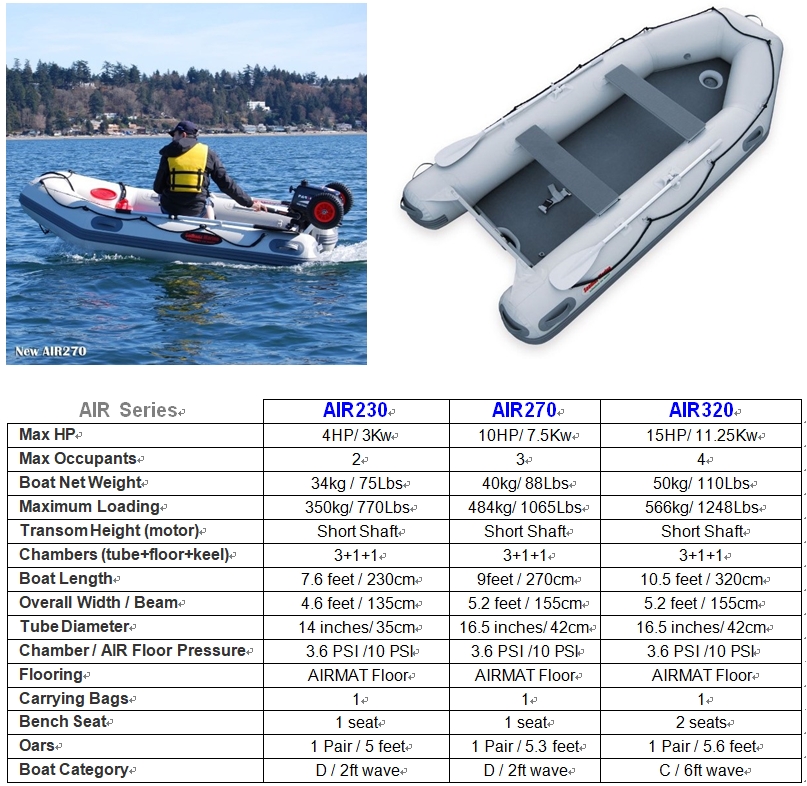

Seamax AIR Series is the boat with high pressure Airmat floor. The Airmat floor material is made by the most advanced modern technology with two layers of fabric held together with thousands of polyester cross stitches. When inflated, this type of floor becomes as rigid as a traditional hard floor. The advantage of this type of floor is that it is much lighter, absorbs bumps, resists tears and rolls up with the boat. An extra durable EVA protective layer is pre-installed on all new long lasting Seamax boats' airmat.

New Version had been made wider and benefit from transom moving backward, the boat also have longer internal space than before. This line will become an good option if you buying a yacht tender or looking for light way easy carrying.

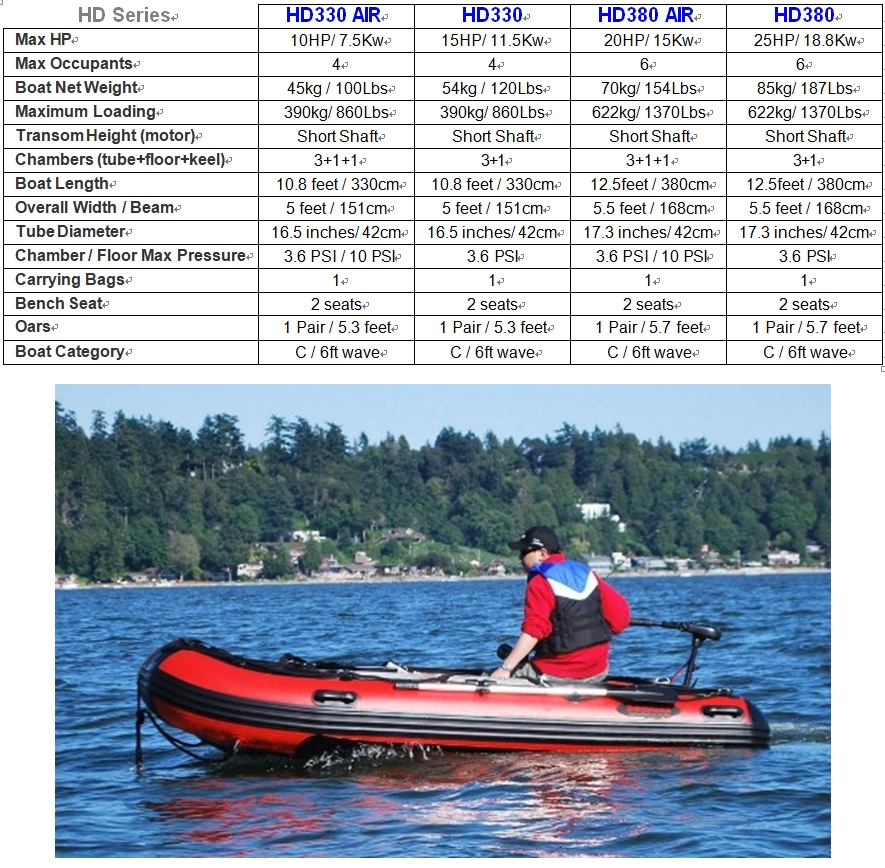

SEAMAX HD SERIES comes with an Aluminum floor, HD330 also comes with an AIRMAT floor option more suitable for creational portable use. Easy to set up. This recreational inflatable boat will take you for a fun day of exploration at the bay, river or lake. It will take you there, away from the waters edge and closer to the fish. If you like to spend weekends being closer to nature, then an inflatable boat is for you. If you have an RV or go camping, most likely you will be near the water. Take an inflatable boat with you. Once deflated and folded, SEAMAX inflatable boat takes up about as much space as a medium bag. You can store it in the trunk of a car, locker, under the stairs or in the corner of the garage, ready for the next weekend or holiday.

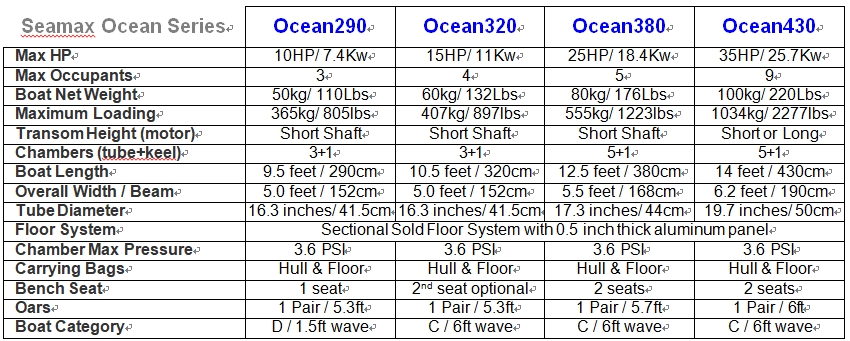

SEAMAX OCEAN SERIES comes with an Aluminum floor, the boat has many heavy duty design and built up to 14ft. Thicker 1.2 mm material for entire boat bottom. Seamax developed reinforcement design for keel, transom underneath, and pontoon bottom. Heavy duty life line around the entire boat. Secondary life line on the inside of the boat. Heavy duty rubbing strake around the boat and keel bottom. Solid 1.5" thick transom made by top grade marine birch plywood. The new Ocean series comes with a larger cockpit space by moving backward its transom, the aluminum floor is easy to maintain with its exceptional resistance to all types of impact. Ocean series is the most popular boats for recreational fishing. Ocean380 and Ocean430 is with 5 pontoon chambers better and safer.

Ocean380 - Seamax Best Seller since 2010

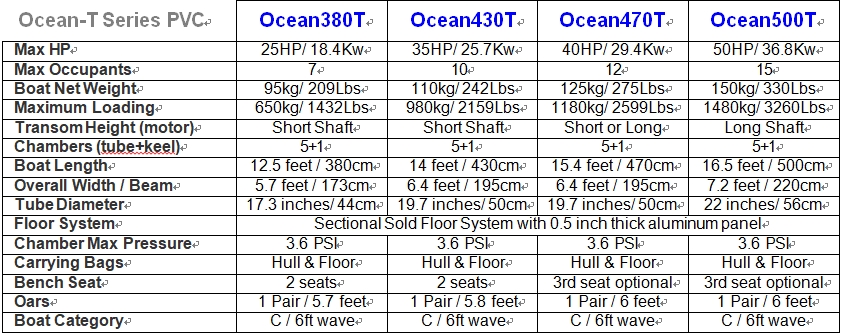

This series will deliver high quality, heavy duty and full features inflatable boats. It can meet all the requirement of entry level commercial inflatable boat. Ocean T series is using 1.2mm PVC for chamber and bottom, plus many special reinforcement application applied. Ocean T series has Seamax highest standard well built for any recreational and commercial use.

Commercial grade boat fabric for main construction; Four layers overlapped chamber seam structure (Feature Code: FOS); Keel Center Inner Reinforcement (KCR); Transom Stabilizer & Reinforcement Design (TSR); Hull Stabilizer Bar Structure (HSBS); Seamax special feature also including: Dual Heavy duty life lines; Heavy duty boat bumper around the boat and bottom; Heavy duty D-Ring & Towing Ring patches.

Seamax is a dedicated manufacturer of Seamax inflatable boats. The PRO Ocean-T series is our top of the line model and is offered in Hypalon. The PRO series uses a new 1" thickness heavy duty aluminum sectional floor for heavy duty, and also has multi point reflective plates on the hull for night navigation. The Ocean Pro series is the perfect inflatable boat for military, rescue and commercial applications. We offer this boat for up to 20ft (6 meter) model and dual motor version available. Don’t forget, this is still the foldable inflatable boat and we can ship the boat in the boxes to anywhere in the world. Seamax can build such a great boat since we keep doing research and development in the boat industry for many years. If you want to know more information of this line, please contact with our sales team.

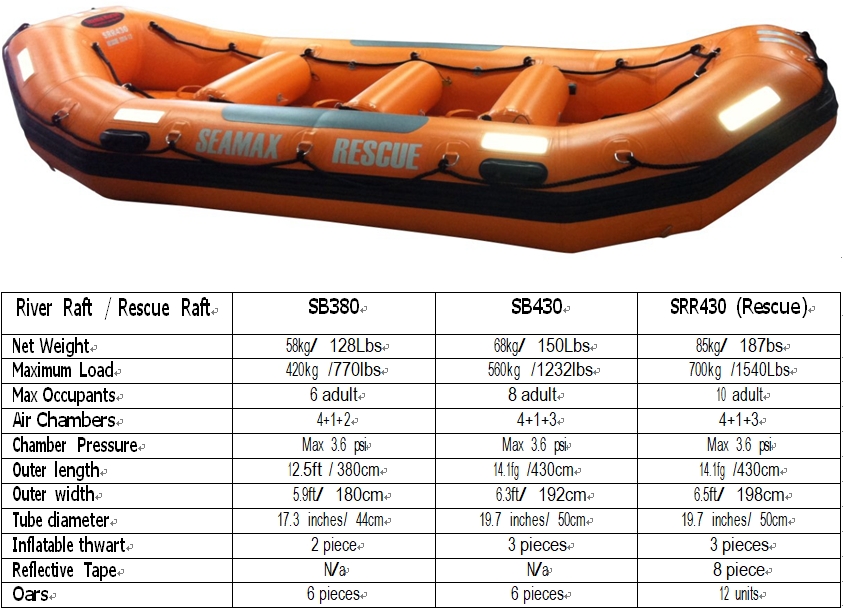

River rafting is a tough sport and the rafts must be made to handle the bumps, scrapes, rocks and other challenges unique to rafting. SEAMAX RIVERSTAR raft is fully wrapped, built tough with a heavy-duty floor, the bottom wear patches from bow to stern, side rubbing strake, convenient, reinforced D-rings, and maintenance-free valves and overpressure valve. The self-bailing floor, with heavily reinforced drain holes on the sides, is permanently attached so there are no bulky ropes or time consuming lacing. The floor design consists of a heat welded, zipped-in bladder of urethane coated nylon inside a protective pocket.

Seamax 14ft River Raft (SRR430) Rescue

Seamax Rescue raft is our special version only available at 14ft model. It is designed to carry heavy weight and person. The raft can be towed after the power boat. It uses the heavy duty orange color fabric to build, the raft has total 8 chambers, hot welded seam, reflective tapes, dual life line and many more.

Note: The rescue is not a in stock model, Seamax only produce this model as special order and the leading time is min 3 months

To protect the boat and its accessories - Never use a sharp knife to open the box. Two person to move the boat from the boxes. Don’t drag the packages on the ground.

Before you unfold the boat, take a good look at how the boat is folded together. Unfold the boat on a flat surface, inspect and check if all the components are in new condition and not damaged in anyway such as: valves, plywood seat, foot pump, oars, aluminum side joiners, floor boards, repair kit and carrying- bag. Remove all components from the box, Find a flat surface and unfold the boat, take the floor boards out along with the side joiners. Inspect and familiarize yourself with all the components and the safety features of your new inflatable boat. Knowing the functions of all the components of your boat is very important .Not only for safety reasons but to assist in any questions or concerns you may have.

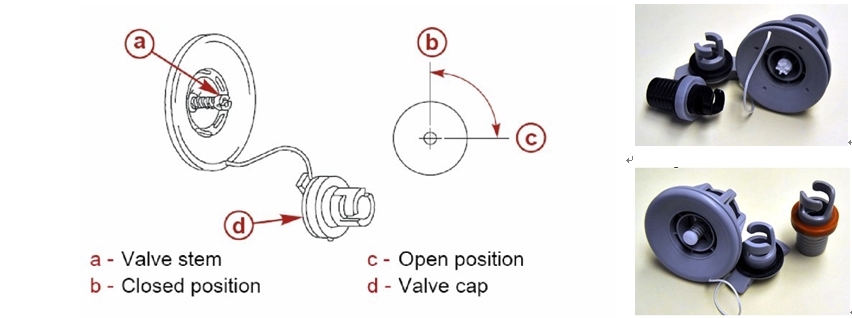

All air valves are preassembled and tested for leaks. To fill remove the front cap and insert pump-hose twist to lock, ensure that the air valve is in the inflate position. You will notice that there is a 2 position valve stem. Push or Push and twist for the inflate position repeat the opposite direction for the deflate position. Each SEAMAX inflatable boat comes with a spare valve and valve wrench

When the boat is new from the box, all the air valves are at OPEN position. Close the valve before you connect it to the air pump. So the chamber can hold the air after the pump hose disconnected. If you forgot to turn the valve to CLOSED position, then it may waste your time to work 2ND time. When you inflate the boat after it assembled, you should start with the rear pontoon chamber on each side, then the 2 middle chambers (if available), and front (bow) chamber & is the next, keel chamber is the latest. (Pontoon & Keel chambers between 2-3 PSI is the normal working pressure for an inflatable boat, Max to give 3.6 PSI)

Double check all valves and make sure they are all in good condition, you can also use the included valve wrench to ensure all the valves are seated tightly against the floor material. To ensure that the valves are in the correct position push in and twist the valve stem should be in the up position. To determine this use the foot pump to pump some air in the floor and then remove hose, if the valve stem is in the correct position the air will not escape, if it does push down valve stem and twist until valve stem pops up.

Locate the foot pump and familiarize yourself with the operation and installation of the air hose into the side chamber air valves. Inflate the side chambers to about 20% of capacity .this is done to pull the floor fabric away from the side chambers and makes the floor installation much easier.

The new Seamax boats may come with one or more over pressure relief valve and nearly model is Bravo VA100. It can protect the inflatable boat from excessive pressure due to over-inflation or increases caused by thermal excursion. The valve can be left in the “OPEN” position or else left “CLOSED” position, with periodical control opening and consequent deflation. The stopper is movable and the opening and closing are made by rotating the stopper with the palm of the hand pressed to ensure that the colored point meets with the reference point. For assembly of stopper by the manufacturer, a hexagonal key is needed. This valve is very reliable, very precise, 100% tested and suitable for use in accordance with the Seamax boats.

Photo is showing the Bravo model only. Your boat could be installed a different version and it is normal

The air floor is designed to be light weight and installed once, its design allows the floor to remain in the boat and be deflated and folded up with the rest of the boat. Seamax air mat floors are specially designed using two layers of fabric held together by thousands of polyester cross threads. Inflating this type of fabric with high pressure air provides a very rigid yet light weight floor. This provides the versatility of a tradition hard floor with the ease of installation. We suggest the Seamax 12V electronic pump to work with the boat (SUP20DB or SUP16DB) since the floor chamber needs over 8 PSI Pressure to be rigid.

Unfold the floor on a clean flat surface that is free of any sharp objects that could damage the air mat Lay the floor flat and ensure that all valves are snug and the air valve is in the closed position. Install plywood slat in holder(under the 2 strap) this is to provide the support to push down the inflatable keel to provide a deep V keel under the boat .check over to make sure there are defects.

Inflate floor with provided foot pump, once inflated inspect and become familiar with the design and how it will fit in the boat. Once you are familiar with the floor deflate (push the valve stem in and twist) the air mat. Take the air series boat and lay out on a clean flat surface, pump the air champers of the boat to about 50%. This will pull the fabric away from the inner sides of the chambers of the boat to make installing the air mat much easier. Install the air mat with plywood support down into the boat. Make sure that the hole in the front lines up with the valve on the inflatable keel, once installed in the bottom of the boat finish inflating the sides , once that is done inflate the air mat floor. You can double check the positioning as you go along by pushing down on the edges of the floor as you inflate it .When you have the floor inflated and in the proper position, inflate the keel. The plywood support will force the keel down to provide a deep V on the bottom of the boat; this will provide added stability in the water.

You can inflate and deflate the boat and air mat floor together and roll up as one piece. Wash and clean the sand and dirt from the air mat floor after each use to avoid sand or dirt from getting inside and damaging the air valve. Always inflate the keel chamber only after you have inflated all other chambers of the boat and floor. And the first time you install floor and inflate the boat it may take up to 60 minutes to complete. If you use the boat as the tender on your sail boat or power boat, please make sure you can follow the boat user manual and your best knowledge to take good care the boat. We suggest using a Seamax boat cover to protect the boat from UV & Heat and suggest Aurora Marine boat care products.

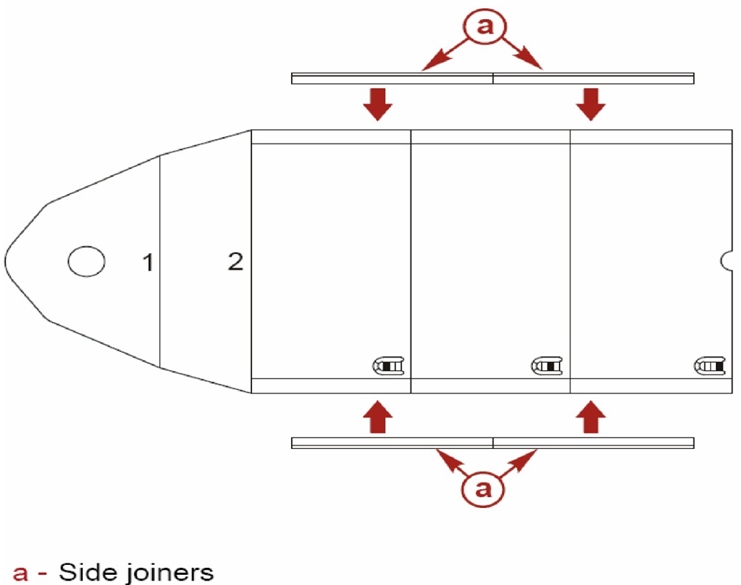

The floor boards included with each series will vary according to the size of the boat .The floor boards must be installed into the boat before the boat is fully inflated. Make sure you place the floorboards in the boat in numerical order. 1 fits into 2, 2 fits into 3, 3 fits into 4 (if required) 4 fits into 5 etc. Base on different boat models, the number of floorboards and side joiners’ combination will be different.

The floorboard system is very important for a Sport Inflatable Boat; you should not miss any parts in your boat assembling. After your boat fully assembled and inflated. The created structure will be super solid. You can put your big outboard motor to reach fast speed, carry the entire passenger on the boat to have a nice time together, load all the gears to fishing or do your boating trip.

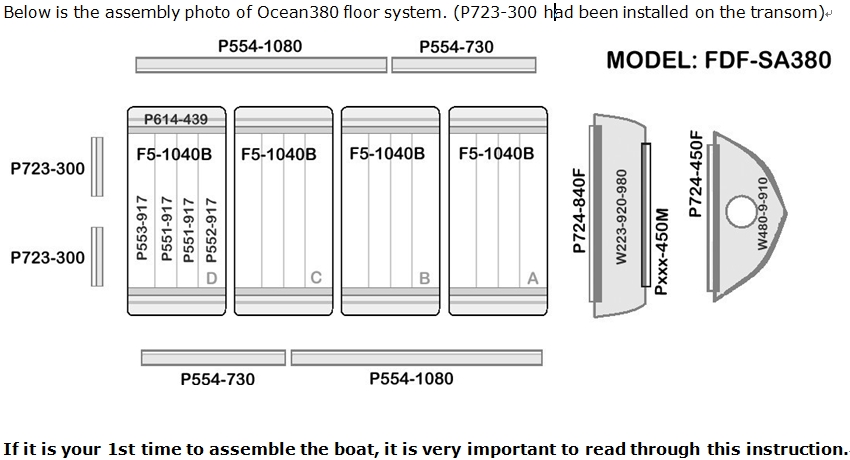

With each boat there are 2-6 side-joiners which you have to install on the sides of the floorboards. These joiners lock the floor in place to become a very stable platform for the boat.

You will notice that the first couple of times you install the floorboards it will be a little difficult, this is normal. After a while it will all go easier because the material will have stretched. Once inflated a few times the installation of the floor board will be very easy.

To understand below tips could help your boat assembling faster and easy:

• Pump up the boat – boat had been folded in the box for a while, pump up all the pontoon chambers to let the boat material expanded. And then you can deflate the chambers to start the assembling.

• Use a 12V electric air pump – when assembling the floorboards, the related chamber(s) air

capacity may need to be adjusted right for your current action. You can inflate or deflate the certain chamber(s) to reach the best position. A 12V electric air pump will help your job much faster &

easier.

• Soapy water – Boat is designed as right fit with the floorboard system. A new boat could be tighter at the beginning. Soap water helps the floorboards and side joiner get in placed easier and fast.

Spray the soap water on the chamber fabric, floorboard edges and side joiners. So they won’t be that easy to jam together. You can save lots of man power when you can have a small bottle 5% soapy water.

• Bottom support – When you placing the side joiners, the space of boat inner edge is very tight since the floorboard already in. You can use your boat aluminum oars or an 8ft 2x4 wood lumber to place at the bottom of boat as the temporary support. The end part of this support must be over the transom few inches. This additional support can lift up the boat edge for few inches, you can have more room to insert the side joiners. Also this additional support can help all the floorboards placed in a straight line, it helps the side joiner to be kicked in.

1. Clear a flat surface that is clean and free of sharp objects. Unfold the boat and spread it out flat.

2. Start with the front plywood floorboard(s); Slide it into the bow, push this as far in the nose as possible or until the valve base of the keel is in the middle of the opening in the front floorboard. Put the next plywood floorboard after the front floorboard

3. Place the rear floorboard (the highest number on the board); push this one as far as possible under the transom. To bend the transom a little bit can help the floorboard going underneath of the blocker.

4. Fit the remaining floorboards together one by one. Finally, the 2 middle aluminum floorboards are forming an inverted V shape. Align the side edges of the floorboards so they are straight, and then push down slowly on the V?joint to flatten the floorboards.

5. Attach the side joiner onto each side of floorboards within the recessed floor portion. (The floorboards are strengthened with the side joiners installed on the floorboards. Position these side joiners: 4-6 inches from transom, remain no gap in between each 2 side joiners).

6. Fully inflatable the pontoon chambers starting from the 2 rear chambers. The 2 rear chambers should contain the air as their max capacity, since those 2 chambers will support the transom also. Keel chamber is the last chamber to be inflated.

NOTE: Slowly operate! Make sure the boat fabric won’t jam with floor board when pushing down.

You can also search the keyword ‘Inflatable Boat Assemble’ to watch video from YouTube. Those video may not be recorded by Seamax. But the idea is same.

Inflatable Boat Assembling Video Link is available from Seamax Website Download Page

Tips: When you insert the side joiners, you can place a long support bar (2x4 wood) or your aluminum oar under the boat bottom, make sure the oar handle is under the transom. So it helps to left up the edge and give your hand more space, at the mean time the aluminum floorboards are lined up. You may save lots time to work on this part if following this tips.

Seamax Inflatable Boat are all built with V Bottom and it can called V-Hull. V-Hull consists of a separate longitudinal inflation tube keel located beneath the floorboards. Once this keel chamber inflated, it provides a moderate V-keel at the bow of the boats by pushing the fabric floor down and away from the floorboards. Handling and performance is greatly improved as the keel cuts through the water cleanly. An added benefit is the extra buoyancy and flotation.

IMPORTANT NOTE OF BOAT INFLATION:

• Best not inflate or deflate one air chamber at a time. When inflating or deflating, maintain a balanced air pressure between air chambers to prevent stress or potential damage to the inside diaphragms that separate the air chambers.

• Do not use any type of air compressor to inflate the boat.

• Install the removable seat before the boat is fully inflated. Hook the flanges that are located on the bottom of the seat into the nylon straps on the side air chambers.

• Do not inflate the keel until floorboards are installed.

• Start by inflating both side chambers. Then inflate the nose. After you have inflated these 3 or 5 compartments you can start inflating the keel.

• Remember that air temperature and direct sunlight can have an effect on the air pressure for up to 2 PSI when in a cold morning and hot afternoon.

1. First Insert the oar piece in to the oar holder since new holder may be tight.

2. Put the rear piece into the oar lock stick. Join two pieces together, click the oar click in.

3. If it is not fitting well, switch over to other piece to try again.

4. Screw up the oar lock cap, finished & ready for use.

OAR SPEC - Two pieces oar, Blade piece & Handle piece; 5.3FT & 5.8FT Assembled Length; Oar handle diameter: 1 ¼ inch; Oar lock hole diameter: 3/8 inch.

SEAMAX inflatable boats come with two styles of self-draining system. To test the valve, while in a forward motion remove the plug from the drain and the water will automatically run out. The inner diaphragm will prevent water from returning. After the water has been drained, replace the plug. Make sure you have pulled out the black plug when you are sailing or towing the boat. It is important to keep the self-draining system clear. When you service the drain valve, please make sure the drain hole & drain valve can have the sealant sealed properly. We suggest Sikaflex 291 or 3M 5200 marine grade sealant to be used.

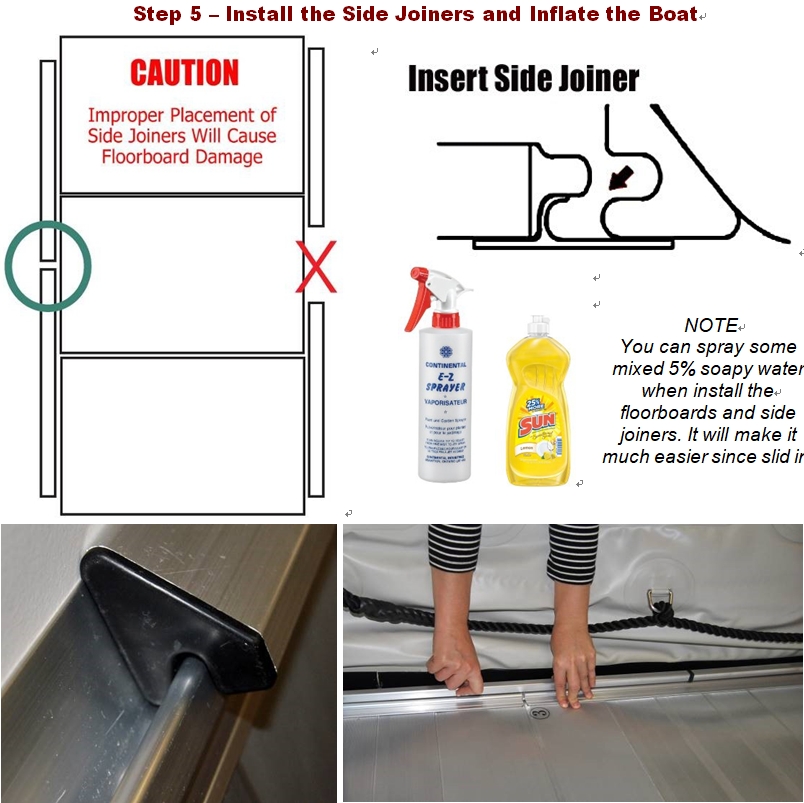

Choose an outboard for the boat that is in accordance with the horsepower range and limit. Refer to the Specification table in this manual or the manufacturer's plate on the boat for the maximum outboard capacity. Install the outboard along the centerline of the boat transom. Fasten the outboard to the transom following the recommended installation instructions provided with the outboard or its manufacturer. Check outboard for tightness on transom before each use. When you install an outboard motor, make sure you place it on the motor bracket at the transom and tighten the butterfly bolts to the transom Check after 15 minutes of boating to ensure the butterfly bolts are still tight to the transom.

Seamax inflatable boats have short shaft and long shaft transom models. The short shaft motor is to fit 15-16 inches height transom. The long shaft motor is to fit 20-22 inches height transom.

1. Check the inflation pressure of the air chambers. Remove any obstruction from the drain valve.

2. Check the outboard for tightness on the transom. Motor over 20HP need to install the bolts.

3. Know the fuel capacity and cruising range.

4. Check that the lanyard stop switch for the outboard works correctly.

5. Be sure the boat is not overloaded. Check the boat capacity plate for weight capacity

6. Be sure there is an approved personal flotation device of suitable size for each person aboard and readily accessible (by law).

7. Check that the paddles are in the boat in case of engine trouble.

8. Be sure the operator knows safe navigation, boating and operating procedures.

9. Have a ring type life buoy or buoyant cushion designed to be thrown to a person in the water.

10. Arrange the passengers and load in the boat so the weight is distributed evenly and everyone is seated properly.

11. Instruct at least one passenger in the basics of boat handling and the starting and operation of the outboard, in case the driver becomes disabled or falls overboard.

12. Before departing, tell someone where you are going and what time you expect to return.

13. No alcohol or drugs on board, it is illegal to operate a boat while under the influence of alcohol or drugs.

14. Know the waters and area you will be boating; tides, currents, sand bars, rocks, and other hazards.

15. Check that all personal safety gear is on board (whistle or noise maker, bailing can, floating rope, water proof flashlight)

16. Ensure the operator has a boating license

If the inflatable boat is to be towed by another boat, the inflatable boat must be empty. Remove outboard, fuel tank, and equipment. Attach a line between the towing rings to form a bridle. Attach a towing line to this bridle and tow the boat at slow speed. A Front Towing Line has been included in all Seamax boats.

AIR LEAKAGE

If one of the air chambers should accidentally deflate while you are operating the boat, shift the weight to the opposite side of the deflated chamber and slowly head for shore. Due temperature difference the

pressure can increase or decrease. It may not lose more than 20% of the pressure in 24 hours by the Inflatable Boat’s Standard regulations check the following steps it this should happen.

1. Ensure all valves are securely tightened, Check if all valves are clean.

2. Inspect for any damage to the air chambers. Check the seams.

3. Use a mixture of water & 10% liquid soap to test for leaks. Check bubbles of the leakage.

4. Report to seller for assistant if any air leakage found.

WATER LEAKAGE

1. Check if the self-draining valve is clean and clear.

2. Check for damage to transom or boat bottom.

3. Take out the floorboards, fill the boat with water on a dry surface watch for wet spots

4. Report to seller for assistant if any water leakage found.

BOAT HIN PLATE

1. HIN Plates provides the information to locate lost, stolen or boats subject to recalls.

2. Please remember to register your inflatable boat with seller & government boat license office.

3. Do not modify or make change of your boat Hull Plate.

4. Report to seller, police and your insurance company if your boat got stolen.

You can keep your boat clean with simple soap and the water. When you find persistent stains like oil and tar, you can remove them with some thinner. Always clean the boat with fresh water like doing your car wash at home. It is important to check the valves every time. The transom, wooden seat and floorboards are made out of plywood and are treated with a waterproof paint. They need to be dry out after boat wash and storage. If the damage according to the transom or front wood floorboards found, you can scour and repair the plywood with marine sealant, primer and outdoor paint. If the damage found is serious, you can take some pictures and contact with us. * Refer to Aurora Marine boat cleaning products.

The boat should be cleaned and rinsed with fresh water before being placed in long term storage. To prevent fabric discoloration from marine growth or polluted waters, do not store the boat in water for extended periods of time. After washing, allow the boat to dry thoroughly before placing into storage. The boat can be stored inflated or deflated. Store the boat in a cool, dry area that is protected from excess exposure from the sun or heat. Cover the boat to block direct sunlight exposure if the boat is to be stored outside for an extended period of time. The boats fabric material is flammable! Keep away from open flame and any heat sources. If you store the boat in your boat or RV, please make sure the cabinet must be cool at the day time as well.

The repair kit included with the boat is a one part glue operation and used for emergency minor repair. For a permanent repair, a two part adhesive for PVC fabric should be used. This two part adhesive and patching materials for PVC fabric are available in the repair kit.

Small tears and punctures in the air chambers which are 1cm (0.393 in.) or less, can be repaired in an emergency. Larger areas, or if the patch will overlap a seam, should be patched by a professional repair person. If you are not sure of the repair procedure, you can contact SEAMAX customer support by visiting our website.

Cut out a patch large enough to overlap the damaged area by 3cm (1.2 in.) on all sides. Center the patch over the damaged area, and with a pencil trace the outline of the patch. Apply masking tape around the perimeter of the outlined patch area to ensure a tight and clean glue line.

Clean the patch area on the boat as well as the backside of the patch, its best to use M.E.K. (Methyl Ethel Ketone) patching solvent and cleaner. Use rubber gloves when handling solvent. After applying the solvent, you will notice that the area will become tacky. This tackiness ensures good glue adhesion.

Apply three thin layers of adhesive with a short bristle brush, in a circular pattern on both the backside of the patch and the patch area on the boat. Allow each layer to dry for 5 minutes before applying the next layer. After applying the third layer, wait 5 minutes and then apply the patch to the prepared area and press down firmly. Using a smooth object (a back of a tablespoon works well), working from the center of the patch to the outside, force out any air bubbles that may have been trapped under the patch. After the patching is complete remove the masking tape, place a 5 pound weight onto the patch and allow 24 hours drying time before pressurizing the repaired air chamber.

Important: Repairing is only possible with a dry atmosphere and the air humidity may not be higher than 60%. More boat repair DIY instruction can be downloaded from Seamax Website.

THIS KIT IS NOT COMING WITH YOUR BOAT, IT IS AVAILABLE FROM SEAMAX ONLINE STORE.

Mix 5% hardener (treatment) to the glue before use. Maximum mix 8% hardener when Cold Weather 10C-15C or High Humidity 50-75%. Do NOT exceed a mixture of 10% to the glue. M.E.K. is the thinner for PVC glue. If the glue hardens, you can add up to 10% MEK to the glue to reactivate the glue.

Glue mixed with hardener can be kept for up to 6 hours. Glue and hardener sealed in the bottles can be kept up to 3 years. We suggest to use a small painting brush to apply 1-3 layer(s) glue on both material surfaces. Wait 5 minutes between applications to allow glue to dry and then attach the two pieces of material together. Once you have applied the patch, work from the center out with something like a teaspoon to force out any air bubbles and then apply pressure to the repaired area for at least 24 hours. Wait 48 hours for the glue to cure before using.

PVC Glue can be used as one part. For a better result, please do 2 Part glue (glue and hardener) to ensure the overall quality of the repair and extend the life time of the bonding. For any repairs related to air leaks, please use 2 Part Glue.

Note: Suggested to apply the glue 1-2 layers on new fabric surface; 2-3 layers on old fabric surface; 3-4 layers for wood or plywood surface; 2-3 layers for parts or aluminum surface. (The surface of Hypalon boat fabric has a coating layer, sanding the boat fabric to get rid of this coating is a must before gluing.) Only mix the amount of glue you require for the repair. Seal the bottle right away and store it in a cool area so that it may be used again. If the hardener turns to crystals or gets sticky, it is no longer usable. To clean the area that needs to be repaired, use Methyl Hydrate, Acetone or MEK.

Mix 6% hardener (treatment) to strengthen the repair result. Maximum mixture is 10% hardener when weather is 10C-15C or when Humidity is 50-75%. DO NOT EXCEED 10% HARDENER!

This Hypalon Glue mixed with hardener can be kept for up to 8 hours. We suggest using a small paint blush to apply 2 layer(s) of glue to both surfaces Wait 5 minutes between applications to allow the glue to dry and then apply the patch to the repair area. Use a spoon to work out any air bubbles starting from the center of the patch and then apply pressure to the repair. Wait 48 hours in high temperature to cure.

Only mix what you need for the repair. Seal the bottle right away and store in a cool area until you need it again. If the hardener turns crystalline or sticky, please replace with new hardener. This glue and its hardener is a brown color.

NOTE: If the Hypalon Fabric is with finished coating, this coating must be sanded before applying the glue. The finished surface will feel like the card tire’s rough surface. Also sand the Rubber Parts contact surface except factory pre-sanded. (Suggest #80 - #120 sand paper).

Seamax develop, manufacture and carry in stock a large amount of inflatable boat accessories. Always visit our website for more products and information. You can also find them from our Amazon sales chancel. We can only list some of the popular models here in this boat manual.

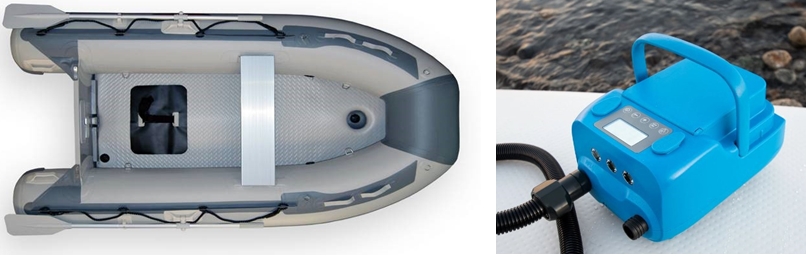

Seamax SUP20D PRO Signature Edition air pump is an upgraded version in the SUP20 pumps family. Programmed intelligent proactive digital controller, voltage sensor, temperature sensor, and overheat protection for managed dual-stage inflation. Backlit LCD display and audible indicator to provide real-time working status to users. Wide range of working temperature and humidity. Regardless of daily use during the season or occasionally use in a year, this high-quality air pump can always do a good job.

Seamax SUP 16DB PRO Double Stage 12V air pump is a new model in Seamax pump family. Thanks to the intelligent control system and its newly designed power control unit, the air pump is great to use with the inflatable boat, SUP, and tent. This DC electric air pump can be powered by its built-in 6AH Lithium battery after charging or through a standard extremal 12V charger socket in a vehicle. It can quickly reach and automatically stop at the user pre-set air pressure. The deflation port helps to quickly deflate the air chamber for easy folding and compact size storage.

With a built-in flash light and 2 USB charging ports, it can be used in the dark environment and conveniently helps to charge the mobile devices. It serves as an all-in-one solution for outdoor sports players. Pump user manual is included in the package and downloadable from our website.

This new Seamax version also has built-in a smart monitoring feature, when the pump starts to inflate, the computer monitors the real-time pressure in every second, based on our Self-Developed smart pump formula, it can find the pump the best timing to switch to 2nd The computer also monitors the pump internal temperature and continued working time, Auto Stop Protection feature has been built-in.

Seamax Deluxe Boat Launching Wheels Set originally designed with 3D-work by Seamax Marine back in 2011, Now it is the 2nd edition released in 2019. Seamax Deluxe Boat Launching Wheels system is made by the marine grade T6 aluminum alloy with CNC processing and shiny looking anodized coating against the corrosion. Thus the product is good for saltwater use. Small parts are all made by solid stainless steel and reinforced Nylon. The air-filled tire is lab-tested (1000 LBS), and is great to support a MAX loading of 600 LBS in all condition. A great add-on for inflatable boats.

BENEFIT of its new design - With the 4 stages of length and 4 wheel arm position, the dolly can be adjusted while afloat in the boat, leaving or coming into the dock. The dolly system can also bring different performance positions for boat launching. The wheel arm length increment is 2.5” per stage. Plus the wheel’s diameter, the range of length is 23 - 30 inches.

Seamax inflatable boat covers have 6 series and overall 25 models. Our boat covers can fit the inflatable boats from 6.5ft to 20ft. Each series includes couple of sizes for different tube styles & boat length. Our boat cover sizes under a same series should be with the same width. The bow style will not affect the cover size in most cases.

Our boat cover should be able to cover your boat and the motor. the covers have been designed to fit the boat and its max rating outboard motor. Fabric Specs - Water repellent, mildew and UV resistant; Density 600D/260g/SQM. Elastic string design for quick fitted and released, Multiple Tie-Down Loops built-in, free cover carrying bag included. Max trailer Road Speed 65km / hour (40mile / hour), additional tie-down core will be required.

Seamax Bimini Top has built-in the special eye-end fitting to install on standard oar lock pin (diameter is 10mm / 0.4 inch) of inflatable boat. Seamax aluminum eye-end fitting can turn 360 Degree, it is rigid and more flexible comparing other types in the market.

Seamax Bimini has 5 sizes to choose for different size boats and provide 2 different types of canopy fabric material, Polyester Pigment Fabric and Acrylic Solution-dyed fabric (Sunbrella). Polyester is economic type and we have it in gray color. Acrylic is 60% thicker and heavier, it can offer heavy duty using in outdoor and double life time. We have it in black color as high end solution.

Gray color canopy is the standard, Black color canopy is the Sunbrella type stronger and double life time. Options for Bimini: Pontoon Fitting Patch Kit, Nylon Deck Mount Kit, Rear Support Pole.

We want to introduce our newly developed thermal welded 3 layers Sunlitec fabric. The outer layer of Sunlitec is the special high-performance synthetic fabric similar to Acrylic fabric. It is resistant to sun light UV and many harsh chemicals including salt water. The mid layer is the water resident micro poly fabric foam. It is resistant to temperatures from outside and inside as well as impeding the water from going through and providing breathable performance. The inner layer is the marine grade polyester 300D for protecting the tear and wear from inside and as back support. After the Sunlitec manufacturing process, all three layers stay together as one fabric. It has a solid structure, better performance, looks great and is light weight. We are the only company to produce these boating accessories with Marine Grade Sunlitec Fabric (MGSF). We hope you will enjoy these high quality and affordable accessories.

Sunitec Seat Cushion Bag Combo & Boat Carrying Bag – All Sizes Available